Stainless Ring Gaskets For Petrochemical Gas Industry

Get Latest Price| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CIF,EXW |

| Transportation: | Ocean |

| Port: | Ningbo Port,Shanghai Port |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CIF,EXW |

| Transportation: | Ocean |

| Port: | Ningbo Port,Shanghai Port |

Model No.: R39

Brand: JINGWEI

| Selling Units | : | Piece/Pieces |

The Octagonal cross section has a higher sealing efficiency than the Oval cross section and is therefore preferred. These gaskets are manufactured as per API 6A / ASME B16.20 to suit API 6B and ASME B16.50 flanges.

The Octagonal cross section has a higher sealing efficiency than the Oval cross section and is therefore preferred. These gaskets are manufactured as per API 6A / ASME B16.20 to suit API 6B and ASME B16.50 flanges.

Industries

RTJ gaskets are available as standard in soft metal and in 304, 316 and stainless steels. Versions in other materials on request.

Style R ring type joints are manufactured on oval (2962/R) and octagonal profiles (2961/R).

Both styles are interchangeable in the modern flat bottomed groove.

Octagonal profile joints are interchangeable on flat bottomes groove flanges which have a 23 degree angle groove wall

we supplies ring joint gaskets (RTJ gasket) with the hardness numbers as follows:

| GASKET MATERIALS | BRINELL HARDNESS NUMBER (max) | ROCKWELL HARDNESS NUMBER (max) | IDENTIFICATION |

|---|---|---|---|

| Soft iron | 90 | 56 | D |

| Low carbon steel | 120 | 68 | S |

| 4-6% Chrome 1/2% molybdenum | 130 | 72 | F5 |

| 304 Stainless Steel | 160 | 83 | S304 |

| 316 Stainless Steel | 160 | 83 | S316 |

| 347 Stainless Steel | 160 | 83 | S347 |

| Common Materials | |||

| Material | HB Hardness | Temperature Limitations | Identification |

| Soft Iron | 90 | -60 to +400 °C | D |

| Low carbon steel | 120 | -40 to +500°C | S |

| 4%-6% Cr ½% Mo:F5 | 130 | -125 to +500°C | F5 |

| Stainless steel 304/304L | 160 | -250 to +650°C | S304 or 304L |

| Stainless steel 316/316L | 160 | -196 to +800°C | S316 or 316L |

| Stainless steel 321 | 160 | -250 to +870°C | S321 |

| Stainless steel 347 | 160 | -250 to +870°C | S347 |

| Stainless steel 410 | 170 | -20 to +500°C | S410 |

| Inconel 625 | – | 1000°C | 625 |

| Incoloy 825 | – | 1000°C | 825 |

| Hastelloy C-276 | – | 1000°C | C-276 |

| Duplex | – | 800°C | S31803 |

| Titanium | – | 540°C | TI |

We specializes in ring joint gasket, including ring gasket in R, RX, BX, IX types, Lens Gasket, Weld Ring Gasket and Bonnet Gasket(according to client's drawing). The metal gasket designed for use in high pressure, high temperature application necessitated the need for a high integrity seal. Our products are widely used in flat gate valve, Christmas tree, pipeline fittings, flange, high pressure vessel, oil &gas industry, wellhead assembly, petrochemical industry and the like.

We can offer more than 30 kinds of materials, such as 321SS, 347SS, 316SS, 304SS, Inconel 625, Monel 400, INCOLY 825, Nickel 200, Duplex F44, soft iron, low carbon steel and so on. We could produce the maximum outside diameter is 2500mm. We have over 10 years experience in export business. Our products are sold to Southeast Asia, Middle East, Europe and America and well appreciated by our clients.

Programming interface ring Joint gaskets come in two fundamental sorts, an oval cross segment and an octagonal cross segment. These essential shapes are utilized in pressures up to 10,000 Rubber Seals and Gasket. The measurements are institutionalized and require uniquely notched spines. The octagonal cross segment has a higher fixing proficiency than the oval and would be the favored gasket. Be that as it may, just the oval cross segment can be utilized in the old sort round base notch. The more up to date level base furrow configuration will acknowledge either the oval or the octagonal cross segment. The fixing surfaces on the ring joint sections must be easily completed to 63 smaller scale inches and to be liberated from shocking edges, apparatus or babble marks. They seal by an underlying line contact or an edging activity as the compressive powers are applied.

Q: Are you trading company or manufacturer ?

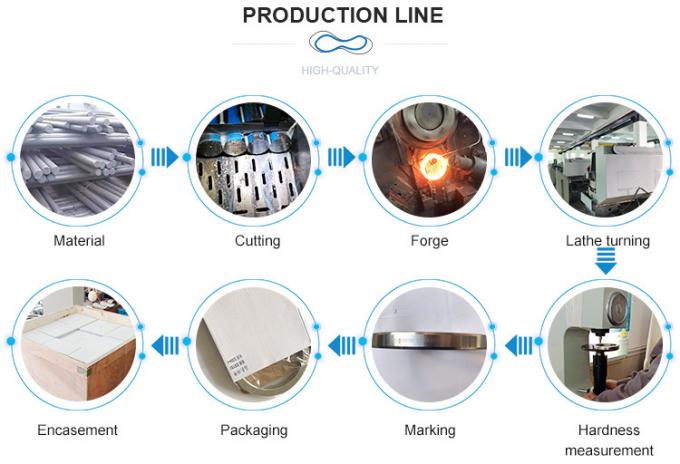

A: We are a professional production enterprise

Q: How long is your delivery time?

A: Generally it is 7-15 days for stock delivery, and 15-30 days for manufacturing goods , but it depands on the quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we can provide you sample, but you need to pay for the sample and freight firstly.We will return the fee after you make an order.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

Q:How can we trust you to make a guaranteed deal?

A:We can trade through alibaba credit guarantee orders, which will fully guarantee the effective rights and interests of buyers and sellers.

Q:Package information?

A:For inner box and master carton are made as per international standards,and we can make special designed for you if need.

If you have another question, pls feel free to contact us.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.